How to explain UPVC windows?

UPVC (Unplasticized Polyvinyl Chloride) windows are a type of window made from a plastic material called UPVC. This material is known for its durability, strength, and low maintenance, which makes it a popular choice for windows.

UPVC windows are made by extruding the material into shape, which allows for a wide variety of designs and shapes. The frames are then reinforced with metal or other materials to add strength and stability.

One of the biggest advantages of UPVC windows is their energy efficiency. They have excellent insulation properties, which can help to reduce energy bills and keep a home warm in the winter and cool in the summer. They are also resistant to weathering, rotting, and corrosion, which means they can last for many years without needing to be replaced.

What are the advantages of UPVC windows?

Energy efficiency: UPVC windows provide excellent insulation and can significantly reduce energy consumption and costs associated with heating and cooling a building. They are also more energy-efficient than traditional windows and can help to reduce carbon emissions.

Low maintenance: UPVC windows are virtually maintenance-free and do not require regular painting, staining, or sealing like traditional windows made of wood or metal. They are also resistant to weathering, corrosion, and fading.

Durability: UPVC windows are extremely durable and can withstand harsh weather conditions, including extreme temperatures, strong winds, and heavy rain. They are also resistant to rot, rust, and corrosion.

Security: UPVC windows are very secure and can be fitted with multi-point locking systems, making them difficult to break into. They are also fire-resistant and can help to prevent the spread of fire.

Sound insulation: UPVC windows are effective at reducing external noise levels, making them ideal for use in areas with high traffic or noise pollution.

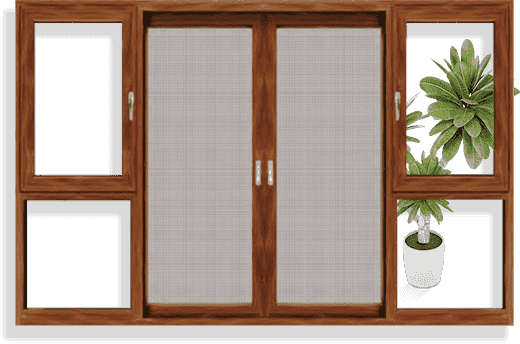

Aesthetics: UPVC windows are available in a variety of colors and finishes, and can be customized to fit any architectural style or design. They can also be designed to mimic the appearance of traditional windows made from wood or metal.

Production process of UPVC window:

Design and measurement: The first step in the production process is to design the window and take accurate measurements of the opening where the window will be installed.

Cutting and welding: The next step is to cut the UPVC profiles to the required lengths and weld them together using specialized equipment. The welding process ensures that the corners of the window are strong and durable.

Cleaning and preparation: Once the window frame is welded, it is cleaned and prepared for glazing. This involves removing any debris or excess material from the welding process.

Glazing: The glass panes are then fitted into the frame, and a sealant is applied to ensure the window is weatherproof.

Quality control: After the window is assembled, it undergoes a rigorous quality control process to ensure it meets industry standards and customer requirements.

Packing and shipping: Once the window passes quality control, it is packed and shipped to the installation site, where it can be installed by a professional.

简体中文

简体中文 English

English