Aluminum doors and windows are building fixtures made from aluminum frames, which are lightweight and durable. These fixtures are commonly used in modern construction projects because of their sleek appearance, excellent structural strength, and resistance to weathering and corrosion.

Aluminum doors and windows are often chosen for their versatility and functionality, as they can be easily customized to fit various sizes and shapes. They are also popular because they are low-maintenance and require little upkeep, making them a practical and cost-effective choice for many homeowners and businesses.

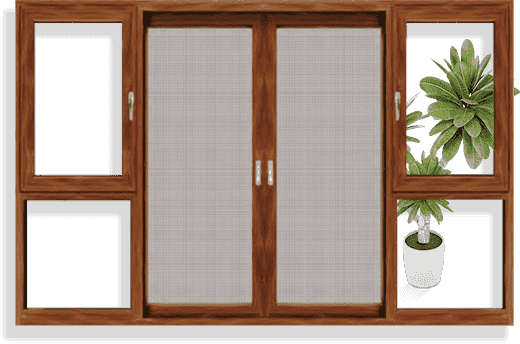

Aluminum doors and windows can be found in a wide range of styles and designs, including sliding, casement, and awning windows, as well as single and double doors. They are often available in a variety of colors and finishes, allowing them to blend seamlessly with any architectural style or design scheme.

What are the characteristics of aluminum doors and windows?

Aluminum doors and windows are a popular choice for residential and commercial buildings due to their durability, strength, and versatility. Here are some of their key characteristics:

Lightweight: Aluminum is a lightweight material, making it easy to install and handle.

Durable: Aluminum is a durable material that can withstand harsh weather conditions, including rain, wind, and extreme temperatures.

Low maintenance: Aluminum doors and windows are low maintenance and do not require frequent painting or staining.

Versatile: Aluminum can be easily shaped into different designs and styles, making it a versatile material for doors and windows.

Energy efficient: Aluminum doors and windows can be designed with thermal breaks and other features that help to reduce energy consumption and increase energy efficiency.

Corrosion resistant: Aluminum is resistant to corrosion and does not rust, making it a good choice for coastal areas or other environments where moisture is a concern.

Modern look: Aluminum doors and windows have a modern, sleek look that can enhance the aesthetic of any building.

Recyclable: Aluminum is a highly recyclable material, making it an environmentally friendly choice for doors and windows.

Production process of aluminum doors and windows:

The production process of aluminum doors and windows typically involves the following steps:

Extrusion: The first step is to extrude aluminum profiles through a machine called an extruder. The extruder pushes heated aluminum billets through a die to create the desired shape and size of the profile.

Cutting and machining: Once the profiles have been extruded, they are cut to the required lengths and machined to precise specifications using CNC machines.

Surface treatment: The aluminum profiles are then treated to improve their appearance and durability. This may involve anodizing, powder coating, or painting.

Assembly: The next step is to assemble the various parts of the door or window frame. This involves joining the aluminum profiles together using various methods such as welding, screws, or adhesives.

Quality control: Throughout the production process, quality control measures are taken to ensure that the finished product meets the required standards. This includes testing for strength, durability, and energy efficiency.

Once the doors and windows are complete, they are packaged and shipped to the customers for installation.

简体中文

简体中文 English

English